ABOUT

ASTARTED IN A SIMPLE POLE BARN – WE’RE NOW A FORCE TO BE RECKONED WITH IN THE SCRAP METAL INDUSTRYdd Your Heading Text Here

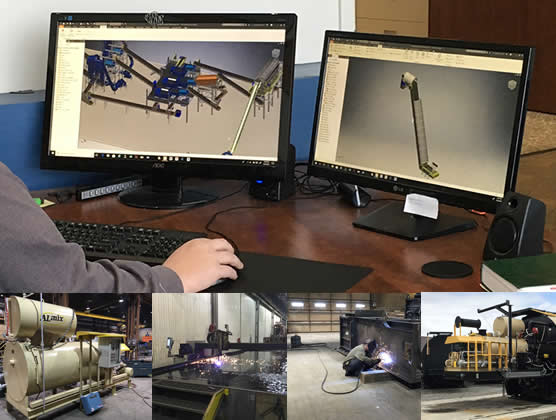

Started in 1998 in a Pole Barn in Auburn, IN, Custom Engineering & Fabrication has grown to 2 facilities with over 120,000 S.F. of manufacturing space to serve your needs. With years of experience in industries like Foundry, Scrap Recycling, Asphalt, Structural Steel & many others we have dedicated staff ready to assist on your next project. Give us a call today and let us assist you on making your next project successful.

What We Use

- Complete process development

- Mechanical Desktop and Autodesk Inventor Series design tools for machine

- Fully programmable Plasma cutting table

- Parts assembly, combination, integration and testing

- Turnkey systems include welding and plasma cutting equipment

- Service, training, documentation, and support; on-site programming services

- Service parts support and complete preventive maintenance services

WHY CHOOSE US

CNC FABRICATION

We fabricate products from raw material using both CNC and conventional fabrication areas.

CNC FORMING

The most efficient method of manufacturing, so that a flat blank receives multiple forms.

LASER CUTTING

Accurately cut even the most intricate patterns with state of the art Laser Cutters.

OUR TEAM

Engineering Team

Name | Position |

|---|---|

Dale Lutz | Sr. Design Engineer |

Michael Hummel | TruNest/Programmer |

Christian Lehman | Design Engineer |

Cameron Kohler | Design Engineer |

Jared Neireiter | Design Engineer |

Jacob Yehle | Design Engineer |

Operations Team

Name | Position |

|---|---|

Todd Walter | General Manager |

Colin Roeth | Engineering & Operations Manager |

Jonathan Lawlor | Engineering & Engineered Sales Manager |

Katie Linder | Business Manager |

Carrie Woods | Administrative Assistant |

Adam Towner | Sr. Production Manager Plant 1 |

Brian Davis | Production Manager Plant 2 |

Derek Blankenship | Maintenance Manager |

Derek Campbell | Project/Installation Manager |